Background

The growth of solar photovoltaics (PV) is one of the most significant engineering achievements of the century. But as solar capacity expands worldwide, exposure to extreme weather becomes an unavoidable engineering challenge. Cyclones, hurricanes, floods, hailstorms, wildfires, and record heat waves are no longer rare events—they are intensifying. For solar, a technology that operates in the open environment with high-voltage direct current (DC) systems, the stakes are severe: structural failure, electrical hazards, risk of fire, system downtime, and even risks to life.

Resilience is no longer a secondary consideration. It is now a primary design, installation, and operational requirement. A single weak point in mechanical anchoring, loose connector, water ingress protection, or shutdown protocol can convert a clean-energy asset into a dangerous liability.

Impact of Extreme Weather to Solar PV Systems

Figure 1: Damage caused to solar panels high velocity winds

Figure 2: Damage caused to solar panels due to floods

Figure 3: Damage caused to solar panels due to fire

1. High-Velocity Winds

Cyclones, hurricanes, and tornadoes expose PV systems to wind speeds exceeding 200–250 km/h. Panels, typically ~2 m² and weighing 20–25 kg, can detach from racking if mounting hardware is under-specified or degraded. Once airborne, modules become dangerous projectiles capable of structural damage and injury. Even partial loosening causes stress fractures, rail bending, or clamp fatigue, accelerating long-term failure. Selection and designing of solar mounting structure according to wind velocity of specific site with redundancy and verified torque values, is essential.

2. Flooding and Water Ingress

Flying branches, unsecured objects, and hailstones striking at terminal velocity can fracture module glass or frames. Cracks compromise the encapsulant, allowing moisture ingress that accelerates Potential Induced Degradation (PID), causes hot spots, and introduces arcing risk. Importantly, damage is often invisible—microcracks detectable only by electroluminescence (EL) or infrared (IR) imaging. One compromised module will reduce power output of the entire string reducing performance of the system.

3. Extreme Snow Loads and Freezing Conditions

In colder regions, accumulated snow exerts additional load on modules and racking. Ice buildup in junction boxes or connectors compromises sealing, leading to delayed water ingress once melted. Structural framing must be certified for regional snow load ratings, and installation angles should allow sliding of snow to reduce accumulation.

4. Wildfire and Smoke Exposure

In fire-prone areas, radiant heat can damage backsheet polymers and melt cabling. Smoke and ash deposits reduce irradiance and introduce soiling losses. Fine particulates also accelerate abrasion on module surfaces. Systems must be cleared of flammable vegetation, and cabling should be flame-retardant.

Operational Guidance

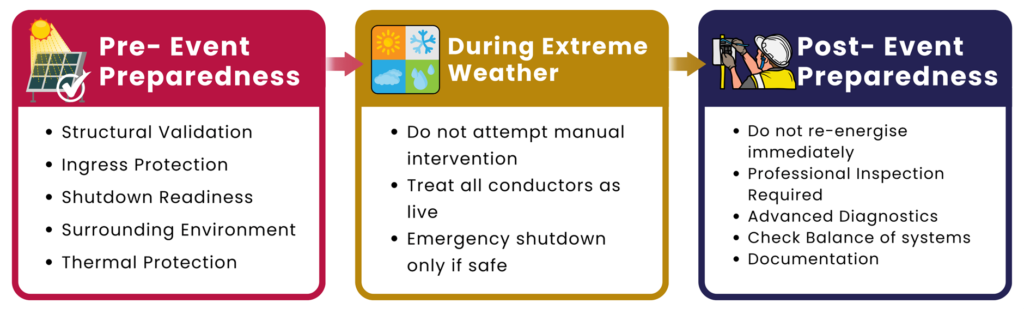

Figure 4: Steps for Operational Guidance

1. Pre-Event Preparedness

- Structural Validation: Confirm mounting hardware meets or exceeds local wind and snow load standards.

- Ingress Protection: Verify sealing of junction boxes, isolators, and inverters; elevate components above known flood levels.

- Shutdown Readiness: Ensure rapid shutdown devices or labeled DC isolators are accessible for emergency disconnection.

- Surrounding Environment: Clear potential projectiles, loose debris, or combustible material near the system.

- Thermal Protection: Check inverter ventilation and ensure inverter cooling system is working.

2. During Extreme Weather

- Do not attempt manual intervention: High winds, flooding, or lightning make approaching systems unsafe.

- Treat all conductors as live: PV generates electricity under sunlight even if disconnected from the grid.

- Emergency shutdown only if safe: Use manufacturer-specified shutdown procedures, located at switchboards or system documentation.

3. Post Event Protocol

- Do not re-energize immediately. Hidden water ingress, cracked modules, or arc faults may persist.

- Professional Inspection Required: A certified technician must test system integrity, insulation resistance, and component safety.

- Advanced Diagnostics: Employ IR thermography to locate hot spots; use EL imaging for microcracks.

- Check Balance of System: Inspect MC4 connectors, combiner boxes, and surge protection devices (SPDs). Replace any damaged SPDs immediately.

- Documentation: Record all findings with geo-tagged photographs for insurance, warranties, and O&M records.

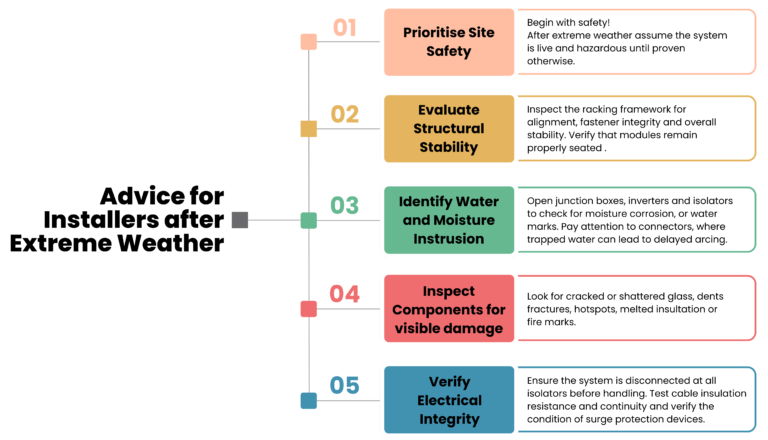

Advice for Installers after Extreme Weather

Installers and maintenance technicians carry the most critical responsibility after extreme weather events. While system owners should never attempt to restart or repair PV systems themselves, it is the installer’s role to evaluate whether the system remains safe, stable, and functional. A rushed or incomplete inspection can leave hidden faults in place, leading to arcing, fire, or system collapse weeks later. IEC 62446-1: 2016/ IS 16960 (Part 1): 2018- Photovoltaic (PV) systems- Requirements for Testing, Documentation and Maintenance (Part 1 Grid Connected Systems- Documentation, Commissioning Tests and Inspection) should be followed.

Further, the following framework outlines the comprehensive inspection and recovery process.

Figure 5: Framework for comprehensive inspection and recovery process

Conclusion

Solar PV systems can withstand harsh weather — but only if designed, installed, and maintained with resilience as a central principle. Extreme weather events are no longer exceptions; they are the new normal. A single loose clamp, poorly sealed junction box, or delayed inspection can escalate into catastrophic failure.

Resilience is therefore not about “extra precautions”; it is about building systems with the foresight that they will face storms, floods, hail, heat, snow, or fire at some point in their lifecycle. By integrating structural robustness, electrical safety, operational discipline, and post-event diagnostics, solar PV will remain not only a clean energy solution but also a safe and reliable one for decades to come.

Credits: This article is based on the original publication by GSES Australia, titled “Preparing Your Solar and Battery System for Extreme Weather Events”, dated March 7, 2025. The content has been revised and adapted to align with the Indian context.

Well written article

Great read! I found the section on post-event protocols especially valuable—reminding system owners not to re-energize immediately and emphasizing the need for professional inspection with tools like IR thermography and EL imaging. That level of detail really shows how small, hidden faults after extreme weather can lead to bigger risks if ignored. It’s a practical takeaway not just for installers but also for anyone managing solar assets.