Introduction

Photovoltaic (PV) technology plays a crucial role in sustainable energy generation, offering significant advantages over conventional fossil-based systems. However, PV modules often contain hazardous materials such as lead, cadmium, selenium, and hexavalent chromium. If not managed properly, these substances can pose risks to human health and the environment, particularly during manufacturing, operation, and end-of-life stages.

A structured Environmental, Health & Safety (EH&S) Risk Assessment is therefore essential to ensure safe handling, sustainable manufacturing, and environmentally sound disposal of PV modules throughout their lifecycle. In alignment with this objective, this article elaborates on the key principles and framework outlined in IS/IEC TS 62994:2019, Photovoltaic (PV) Modules Through the Life Cycle- Environmental Health and Safety EHS Risk Assessment- General Principles and Nomenclature.

EH&S Risk Assessment: Core Concepts and Methodology

EH&S risk assessment is a systematic method designed to characterize and evaluate potential adverse impacts on human health or the environment, with the ultimate goal of developing effective control and reduction policies.

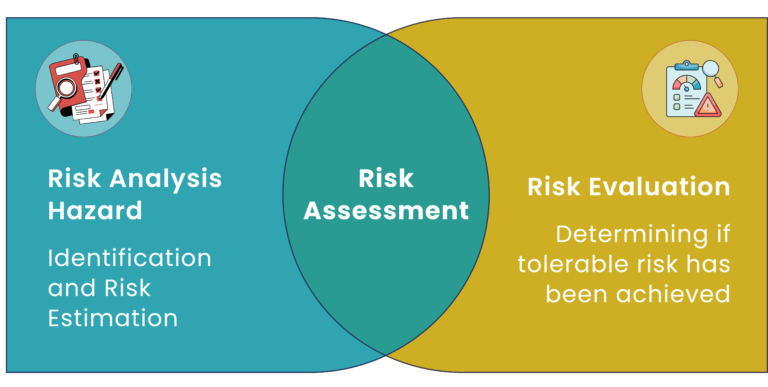

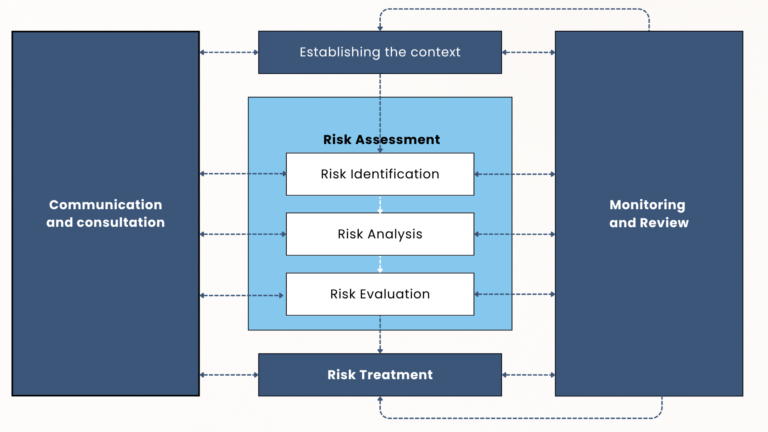

The process of risk assessment is defined as the combination of risk analysis (hazard identification and risk estimation) and risk evaluation (determining if tolerable risk has been achieved).

Figure 1: Risk Assessment as a combination of Risk Analysis Hazard and Risk Evaluation

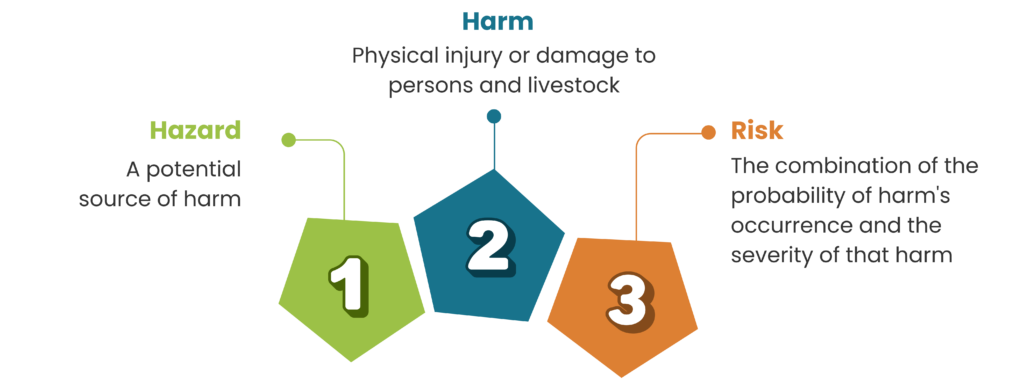

Key definitions fundamental to this framework include:

Figure 2: Definition of Hazard, Harm and Risk

Dual Case Evaluation Methods

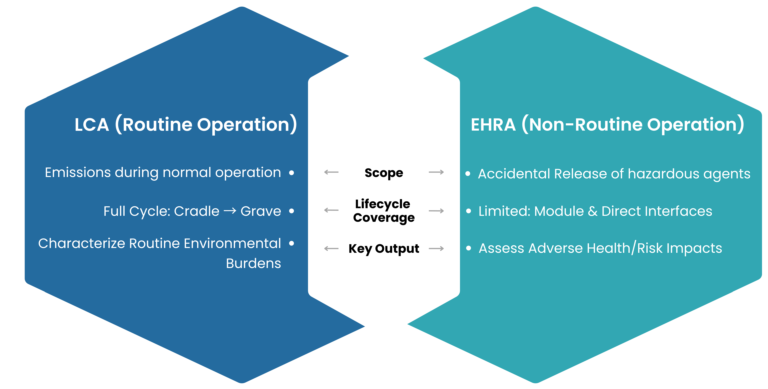

The evaluation methods for EH&S risk assessment based on the operational context, can be of two forms:

- Routine Operations (Foreseen Events): Use Life Cycle Assessment (LCA) to evaluate environmental impacts across all stages—manufacturing, operation, and end-of-life. This includes emissions from material processing, energy use, and recycling.

- Abnormal Non-routine Operation: The specialized Environmental Health & Risk Assessment (EHRA) method is applied. EHRA focuses on adverse health or environmental effects resulting from exposures to hazardous agents or situations, such as the accidental release of substances. The system analyzed under EHRA is limited to the PV module, its supply chain, operation, end-of-life treatment, and its direct electrical and mechanical interfaces with the balance of system components (e.g., inverters).

Figure 3: Life Cycle Assessment (LCA) and Environmental Health Risk Assessment (EHRA) distinction

* This article elaborates the general EHS Framework and the Environmental Health Risk Assessment (EHRA), while the Life Cycle Assessment (LCA) will be discussed in subsequent articles.

Environment Health & Risk Assessment (EHRA) of PV Module

EHRA is the systematic process for examining the effect on human health and environmental harm from a non-routine event.

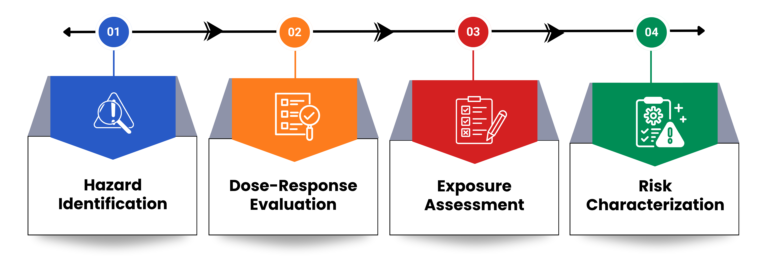

Figure 4: Step by Step process of EHRA

EHRA comprises four main steps:

- Hazard Identification

This step examines the potential of a substance to cause adverse health and environmental effects, using both toxicological data and complementary information like structure-activity analysis. Substances that are the subject of EH&S risk assessment include flammable, explosive, corrosive, or toxic materials.

In manufacturing, this includes process-related chemical and physical hazards. Hazards associated with specific PV technologies and semiconductor deposition processes include:

- Corrosive: Boron trifluoride, hydrofluoric acid, silicon tetrachloride and sodium hydroxide.

- Toxic: Lead, arsenic, cadmium, indium, selenium, and hexavalent chromium.

- Irritating/Harmful: Ammonia, hydrogen selenide, hydrogen sulfide, and phosphine.

- Flammable/Explosive: Hydrogen, silane, and methane.

- Asphyxiant: Argon, helium, and nitrogen trifluoride.

- Dose-Response Evaluation

This is the process for determining the quantitative relationship between exposure and the effects of concern. The determination of a dose-response relationship depends on several critical factors:

- The selection of appropriate extrapolation models.

- The availability of reliable information.

- The use of appropriate datasets selected from those that show the range of possible responses.

- The basis for selecting inter-species scaling factors to account for scaling doses from animal experiments to humans.

- The relevance of the exposure routes used in the studies (e.g., dermal, inhalation, ingestion) to the potential exposure routes and more.

- Exposure Assessment

This process quantitatively and/or qualitatively evaluates human or ecological exposure to hazardous substances, requiring a determination of the magnitude, frequency, extent, and duration of the exposure.

- Emissions: Potential emissions are evaluated during non-routine events such as fire, field breakage, or disposal of a PV module. For fire emissions, existing methodologies include the use of tube furnace and UL1256/ASTM E-90 fire test standards.

- Environmental Fate: Characterizes the movement and transformation of a chemical from the point of emission to the point of exposure, which can impact pathways such as soil, water, and air.

- Air Emissions: Fate is evaluated using methodologies for downwind dispersion, including Gaussian plume dispersion modeling.

- Soil/Water Emissions: Fate is evaluated using methodologies including soil-water partitioning coefficients for soil dispersion and dilution-attenuation factors for groundwater dispersion.

- Risk Characterization

Risk characterization is the final step integrating the preceding three stages. It provides the information needed for decision-making regarding control and protective measures. The process calls for principles of transparency, clarity, and consistency (TCCR) to be applied throughout every aspect of the assessment, which helps the whole process benefit and better ensure success.

Tolerable Risk: For human health risk, compliance is maintained by comparing risk to benchmarks like the Regional Screening Levels (RSL) database. For ecological risk, the Ecological Soil Screening Levels (Eco-SSL) database is used to determine acceptable thresholds.

The integration of EHRA results with the broader risk management process (including risk treatment, monitoring, and review) is crucial for the effective control of risk.

Integration of Risk Assessment and Risk Management

The risk assessment (comprising analysis and evaluation) must be closely linked with the risk management process for the effective control of risk. The results and information provide an improved understanding of risk to decision-makers and serve as a basis for adequate and effective controls.

The relationship between the assessment and management processes shows that the assessment provides a foundation for the subsequent, iterative steps of control and review. The overall process includes:

- Establishing the context

- Risk assessment (Identification, Analysis, and Evaluation)

- Risk treatment

- Communication and consultation

- Monitoring and review

Transparency and consistency in the assessment formulation and planning are crucial precursors to the formal steps of quantitative risk assessment and ensure better success.

Figure 5: Contribution of risk assessment to the process of risk management

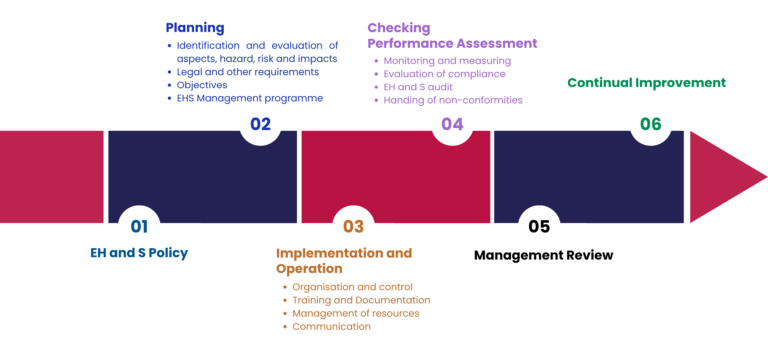

EH&S Management System for PV Modules

The EH&S management system is the structured process for systematically achieving a desired level of EH&S performance, and it involves planning, implementation, operation, checking, and management review to achieve continuous improvement.

Objectives and Principles

The EH&S management system is the process for systematically achieving a desired level of EH&S performance. It has two primary objectives:

- Prevention of incidents or accidents that might result from abnormal operating conditions.

- Reduction of adverse effects from routine operations.

Figure 6: Environmental Management System Model

- EH&S Policy

- Coordination with other organizational policies.

- Specific local or regional conditions.

- Life cycle thinking.

- Involvement and communication with interested parties.

- Work toward sustainable development.

- Planning

- Recognition and determination of environmental and occupational health aspects.

- Compliance obligations and requirements that the organization must meet.

- EH&S objectives and planning to achieve those objectives.

Planning is designed to establish hierarchical safety protocols, including occupational hazard analyses, trainings, audits, and internal workplace safety controls.

- Implementation and Operation

- Safer Materials/Processes: Using safer forms of a chemical, or reducing on-site inventories.

- Accident Prevention: Options to prevent initiating events through safer designs or process hazard analysis.

- Safety Systems: Systems to prevent or minimize releases at the source, such as automatic shut-offs and cooling and containment systems.

- Accidental Release Capture: Systems to capture accidental releases, including secondary confinement, emergency-handling scrubbers, and incinerators.

- Minimize Human Exposure: Measures like separation zones, physical barriers, and emergency preparedness plans.

- Checking and Management Review

- Checking: Internal audits are conducted to determine if the system conforms to planned arrangements and has been properly maintained and implemented.

- Management Review: An organization must periodically conduct a review of its EH&S system. Inputs to this review can include:

- Results of audit and evaluation of compliance obligations.

- Communication from external interested parties.

- EH&S performance of the organization.

- Status of corrective actions.

- Follow-up from previous management reviews.

- Recommendations for improvement.

Conclusion

The future of PV sustainability demands that EH&S Risk Assessment evolve into a dynamic, predictive framework. This requires the EHRA procedure’s data to be tightly integrated with the Risk Management Process for actionable controls. The comprehensive EH&S Management System must continuously translate policy into perpetual safety enhancement. This commitment ensures that the industry’s clean energy goals are anchored by a resilient and safe technology lifecycle.