The fast scaling up of the grid-connected PV market in India has created unhealthy competition among project developers, construction companies, equipment suppliers, and service providers. This, unfortunately, results in the compromise of quality standards in – project design, selection of equipment, and balance of system, installation, and even O&M practice in many instances. A large number of solar power plants have been reported to show poor performance due to known or unknown reasons. Apart from that a number of solar power plants are damaged by storms and gutted into the fire. In this note, we are discussing the performance and safety issues of grid-connected rooftop PV projects.

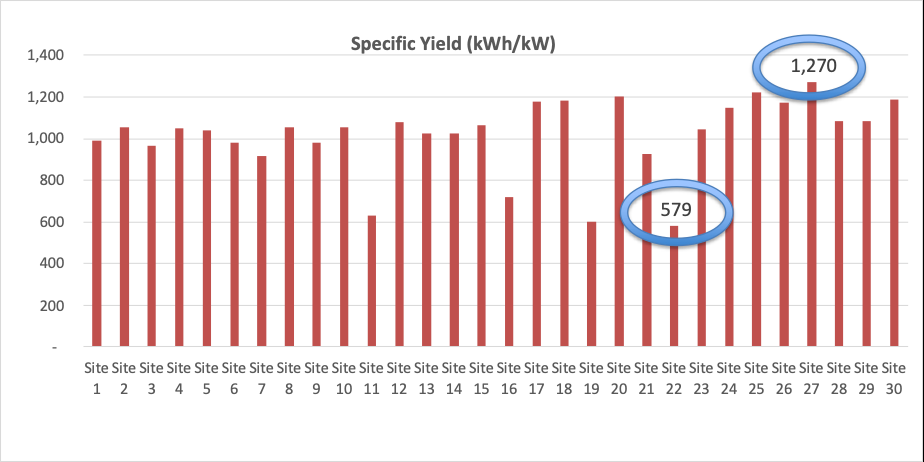

Figure 1: Performance variation in 30 different rooftop PV Plants in the same geographical area

What determines PV power plant performance?

PV systems are generally exposed to a variety of losses due to environmental factors, device limits and manufacturing defects. Such losses include – soiling, shading, manufacturer’s tolerance, temperature, voltage drop, inverter efficiency, orientation and tilt angle of the module(s), degradation of the solar module(s) and any other location specific factors that could have an impact on the plant’s performance. Favourable solar radiation and the best of equipment cannot alone perform well if the system is not designed, installed and maintained appropriately.

Though there are many factors responsible for the under-performance of a PV power plant, this note discusses the following key issues in regards to performance and safety of rooftop PV projects.

Accurate site assessment and planning:

The site parameters that influence performance and reliability of a PV system are – access to solar radiation, near shadow and far shadow, ambient temperature, air flow and ventilation, basic wind speed, height of building, terrain, orientation, dust level and pollution, salinity, humidity, extreme weather conditions etc. A number of parameters are likely to be variable from one site to another even in the same geographical area. Therefore, it is crucial to plan a solar PV project to suit the site parameters, and also to select the right components and customising the design accordingly to ensure better performance and safety. An inaccurate site assessment will lead to wrong design and installation and poor maintenance of a PV system, which eventually follows into poor performance and unreliable system functioning.

Selection of inverter and system design:

A well-designed/installed grid-connected PV system should have fault free operation for many years. Poor system design can result in the PV array operating at voltages outside the inverter voltage window and consequent disconnection of the inverter from the grid for long durations of time. Poor system design in relation to the PV array and inverter, also forces the inverter to operate very inefficiently. In many cases, the owner has been given a prediction of unrealistically high energy yield from their PV system.

Shadow analysis at site and string management:

It is highly essential for shadows to not be cast on the array by structures, trees, chimneys, fences, and other objects between the hours of best insolation. The site specific output from the PV array can only be accurately calculated once the actual solar access is known for the installation site. However, energy loss due to the effect of any shadow is not proportionate to the array area covered under the shadow. When a PV module is partially shaded, the use of bypass diodes in the modules will ensure optimum output from the PV under shaded conditions, However, the maximum power point voltage in the string will decrease. Thus, the design of the PV array strings must ensure that the maximum power point voltage will not drop outside the inverter voltage window when the modules in the string are shaded. Hence, when the effect of partial shadow is unavoidable, selection of an appropriate inverter and placement of module strings according to shadow coverage is critical to enhance the performance of any rooftop PV system.

Figure 2: Selection of right inverter type and placement of modules string can substantially reduce shadow loss

Module cleaning and access to maintenance:

Build-up of dirt on the array can substantially affect system performance. It is essential to clean the modules regularly to maximize energy output from a solar power plant. However, wrong cleaning practices and low-quality water used with inappropriate cleaning means may damage the modules and other array components, lowering system performance as well. It is also essential to train the cleaning personnel on proper cleaning methods and use of appropriate cleaning tools. Cleaning procedures must be based on module manufacturer’s instructions, site conditions, quality of water and adopted cleaning mechanism. It is often seen that PV arrays are not even accessible to carry out cleaning processes on, and it may so happen that one has to step onto the modules during cleaning and maintenance work. While inaccessibility keeps the modules from being cleaned, producing less energy; stepping on them gives way to the development of micro cracks, damaging the modules.

Figure 3: Keeping the modules clean and adopting correct cleaning practice is key to better performance of solar power plant

Safety from wind loading:

Structure failure is a very commonly rising complication in Indian solar projects. In many cases, the structure may not fail as such, but the PV modules are damaged due to high stress or deflection developed in the structure which is often wrongly designed and installed. The main reason for this is inadequate design or wrong design criteria. In many cases structures are conceptualised just to enhance energy generation with no consideration of wind loading. Structural design analysis must include criteria that requires not only protecting the structure from excessive loading but also preventing it from deviating due to permissible deflection and stress on the modules fixed on it. Apart from the strength and loading capacity, an array mounting structure must ensure that the PV array receives optimum solar radiation and reduces temperatures loss by allowing enough air circulation. It is also important to ensure that factors such as structure design, placement, orientation, tilt and shading are aligned with electrical string design and choice of inverter.

Figure 4: PV plant damaged by strong wind

Safety from Fire:

Unlike conventional electrical products, PV modules and wiring do not have an overall enclosure to contain arcs and fires resulting from component or system faults. Grid connected rooftop PV arrays generally operate at 150V – 800V DC voltages, highly capable of sustaining DC arcs. An arc in the PV array can occur due to a faulty or loose connection (series arc), a short circuit due to wrong polarity or failure of insulation (parallel arc). If an arc develops due to a fault in a PV array, it can result in causing significant damage to the array and may also result in damage to adjacent wiring and building structures.

Figure 5: Fire from series arc due to loose connection in the module junction box

Since PV systems contain a large number of series connections, occurrence of a series arc is very common, which may be due to loose connections and poor quality/mismatch of connectors. Parallel arcs are a result of short circuits in the system due to damage of wires or due to connection of wires with wrong polarity. This can cause severe damage to the PV system and building property as well.

Conclusion:

Success of a rooftop PV project is defined by the return on investment which is the direct outcome of reliable operation and lifetime performance of the system. In general PV systems are exposed to a variety of losses some due to environmental factors, some due to device limits and others due to manufacturing defects. The losses will include things such as dirt on module, shading, temperature, voltage drop, inverter efficiency, orientation and tilt angle of the module, degradation of solar modules and any other location specific factors that could have impact on the plant performance. But these are not only the factors that determine PV system performance. Favourable solar radiation and best of the equipments cannot alone perform well if the system is not designed or installed in a technically competent way. Project managers and design engineers must identify the critical site parameters carefully, assess the long term impact on the system and consider them in the design process to build sustainable and profitable solar PV project.