Background

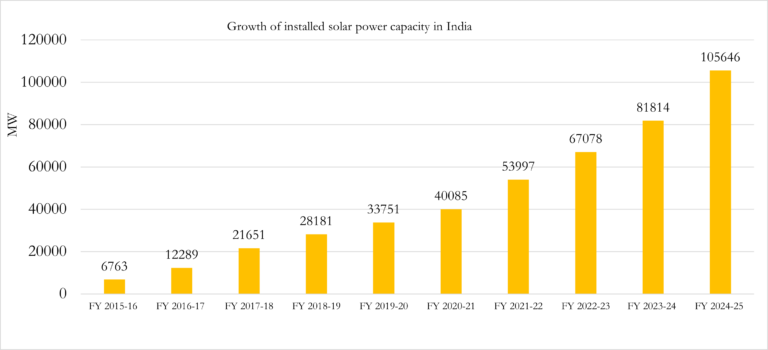

Installed capacity of Grid Connected Solar Power Plants in India has grown from 6763 MW in 2015-16 to 105,646 MW at the end of 2024-25. The rapid scaling up of grid connected PV market in India has created enormous skill gap and significant competition among project developers, construction companies, equipment suppliers and service providers and the unfortunate consequence is that quality standards in project design, selection of equipment and balance of system, installation and even O&M practice being compromised in many instances. A large number of these power plants are reporting poor performance due to known or unknown reasons. Many developers and investors are desperate to improve their power plant performance but failed to understand the reason for underperformance, which is not merely related to regular operation and maintenance issues.

Figure 1: Growth of installed solar power capacity in India

What determines PV Power Plant Performance?

In general PV systems are exposed to a variety of losses some due to environmental factors, some due to device limits and others due to manufacturing defects. The losses will include things such as soiling (dust), shading, module-inverter mismatch, temperature, voltage drop, inverter efficiency, orientation and tilt angle of the module, poor cleaning practice, degradation of solar modules and any other location specific factors that could have impact on the plant performance.

But these are not only the factors that determine PV system performance. Favourable solar radiation and best of the equipments cannot alone perform well if the system is not designed or installed in a technically competent way suitable to specific site conditions. Some of the factors responsible for under performance of a PV power plant are:

- Poor system design

- Poor quality equipment and materials

- Under sizing of equipments

- Improper installation and integration of equipments

- Mismatching of different parameters

- Unstable grid

- Frequent equipment failure and shut down

- Potential Induced Degradation (PID)

- Inadequate O&M planning etc.

A well-designed and installed PV grid-connected system should have fault free operation for many years. Poor system design can result in the PV array operating at voltages outside the inverter voltage window and consequently the inverter disconnects from the grid for long periods. Poor system design relating to the PV array and inverter also force inverter to operate very inefficiently. In many cases, owner has been given a prediction of unrealistically high energy yield from their PV system. This usually occurs due to ignorance or poor estimation of system losses by the system designer or the consultant. Some of these losses are easy to rectify but some require in-depth understanding and testing of the system and components.

Figure 2: Three main concerns for PV system failure

Why PV Power Plant Audit?

The objective of PV plant audit is to ensure grid safety and improve the power plant performance. PV power plant audit identify the root causes of these losses and help to maximise its performance. A simple PV audit process starts with the data analysis process with in-depth analysis of the available wind, temperature, irradiation, DC power output and AC power output data. This allows the auditors to understand the system behaviour and conduct the audit in a systematic manner. An analysis of the design documents allows the auditors to validate the design process according to best practices and industry standards. Bill of material audit is also a critical step in ensuring PV plant durability and reliability. This involves benchmarking the quality of installed components with our internally developed metrics and PV audit experience around the globe.

GSES performs the following tasks during PV Power Plant Audit:

- Performance analysis of power plant from past energy generation data and weather parameters and comparison to estimated yield at design stage

- Analysis of grid availability data and grid fluctuation data

- Analysis of power plant down time (partial or complete) due to maintenance issue

- Review of calibration certificate and the accuracy class of all measuring equipments and compare with the globally accepted practice

- Evaluation of overall construction quality & BOS component performance

- Evaluation of functioning of weather monitoring station installed at the plant

- Inspection of functioning of plant’s SCADA system or data logging system (local & remote)

- Evaluate plant O&M procedures including periodicity of cleaning of arrays, preventive maintenance schedule, fault response time etc.

- Suggest key requirements to prevent preliminary degradation and revenue loss

- Recommend options for upgrading and re-engineering and scenarios

- Cost benefit analysis of different scenarios for upgrading and re-engineering

- Recommend optimal O&M planning to minimize downtime

Good. The point that stood out to me was how poor system design and unrealistic energy yield predictions can be bigger contributors to underperformance than just O&M issues. Highlighting the role of PV plant audits in identifying root causes—right from design flaws to BOS component quality—makes it clear that audits aren’t just about troubleshooting but about safeguarding long-term performance and revenue.