Installing roof-top isolators is mandatory in Victoria and the ACT. It also is an increasingly common practice in other states as a way to enhance the safety of PV installations during maintenance and in emergency situations. However, installing isolators correctly is essential if the full safety benefits are to be gained. This article clarifies the factors that installers need to consider when installing roof-top isolators.

Types of Isolator

Isolators can be rated differently depending on whether it is load breaking or non-load breaking. If the isolator is load breaking, such as the rooftop isolator, it should meet all the same requirements for voltage and current as the DC switch-disconnector installed next to the inverter. This isolator must be non-polarized and rated to handle breaking first fault conditions under load as per AS/NZS 5033:2012 Appendix B2 D.C. Switch-Disconnector Voltage Rating Requirements. If the device is non-load breaking, such as ELV disconnects or string isolators, then the device must clearly be marked as “no-load break” as stated in AS/NZS 5033:2012 Cl. 4.4.1.3. Non-load breaking devices do not have to be rated to break first fault conditions under load and therefore may be rated to PV Array Max Voltage Please note that all relevant electrical state service rules should be followed. For details on the sizing, wiring, and types of isolators see GSES’ articles in previous PVPowers, on the GSES website or go to the Clean Energy Council’s Solar Accreditation website.

IP Rating

Once the isolation device has been selected it is important to ensure that it is installed in a way that protects the device from the weather, and anyone using it from electrocution. To achieve this, the isolator enclosure should be IP rated for outdoor use and be suitable to last the life of the system. To comply with AS/NZS 5033:2012 (Clause 4.2.1) this means using an enclosure rated at IP54 or higher made of UV stabilised plastic, ASA, polycarbonate or metal.

IP Ratings

The ingress protection (IP) rating of an enclosure describes two different properties. The first digit of the two digit rating – describes the ability of the enclosure to resist the ingress of solid material like dust. The second digit describes the level of protection offered against water.It is important to understand that the numbers are independant, so both digits must exceed the minimum requirement of the standard. An IP63 enclosure, while having a greater number than the minimum 54, does not satisfy requirements as the water ingress protection (3) is insufficient.The IP rating of the enclosure is recommended to beat least that of the inverter, with a minimum of IP54. Inverters are produced with several IP ratings that correspond to different applications; IP21 for indoor mounting, IP42 for covered external applications and IP65/66/67 for uncovered outdoor mounting. As such, when an IP65 inverter is installed an IP65 enclosure should also be used.There are many switch type isolators available that are IP 65 rated or higher that are perfectly suited for roof top installation. Similarly an appropriately IP rated box with a DC circuit breaker inside will provide the same functionality. Whatever device is installed, it is important to remember that it is the method of installation, as much as the enclosure itself, that determines whether the enclosure will maintain its rating for the life of the system.

Mounting an Enclosure

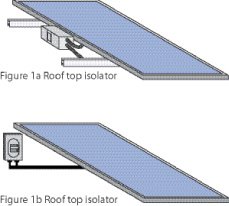

The orientation of an enclosure when mounted is important in ensuring that the IP rating in maintained. Every manufacturer will provide specific recommendations for their product; however a few general rules are:

- No penetration (e.g. conduit entries or screw holes) should be upwards facing. Any upwards facing penetration provides the means for water to penetrate the enclosure as rain falls on the box or as water runs along the conduit leading into the box.

- Enclosure openings should not face skywards. The lid that covers the isolator provides an opportunity for water to enter the enclosure every time it is opened if water splashes from the waterproof gutter into the box. Similarly if the lid points skywards and is not resealed after use, it is an easy way for water to get in.

- Any penetrations made during installation, such as screwing the enclosure to the mounting rail, should be waterproofed using an appropriate gland or gasket. Using silicon does not provide a seal that is durable and flexible enough to last the life of the system.

- The enclosure should be mounted so that it is standing upright or lying on its side. If it is installed in either of these orientations the lid faces the horizon and the likelihood of water entering the enclosure is reduced.

The following diagram from the Clean Energy Council shows the best arrangements.

Beyond the Box

The installation of an IP rated enclosure and roof-top isolator can have implications aside from the enclosure itself. This section looks at some of the common issues installers need to consider.

Conduit Runs

In most situations the cables running from the array to the isolator will only be enclosed in conduit at the edge of the array. If the entry to the conduit faces skywards, or even upwards and is lying across the roof, then the conduit can act as a funnel collecting water and feeding it into the isolator enclosure. Sealing both ends of the conduit using appropriate couplings and glands, and having the entry of the conduit below the level of the enclosure will ensure that water does not enter the enclosure from the conduit.

Dissimilar Metals

When mounting an enclosure to a metal structure such as the mounting rail of a solar array, the method of mounting should be considered. If screws or bolts are used then consideration should be made for galvanic separation. If not, then the fixings can corrode affecting the integrity of the enclosure, or the whole mounting structure.

Shading

One consideration that is often neglected is shading. If the isolator enclosure sits above the level of the solar modules it can cause shading on the array. A small shadow on one cell can dramatically reduce the output of the array and can result in hotspot heating.

Key Points

Roof-top isolators are an important part of PV array safety and maintenance equipment, but if they are installed incorrectly they can be of reduced benefit or even present a liability for system reliability or performance.

- Always remember to read the manufacturer’s installation recommendations and to:

- Seal all penetrations using glands and gaskets, not silicon

- Face the lid of the isolator towards the horizon; a skywards facing lid can let water splash in when opened

- Carefully consider the installation of the enclosure; it can be just as important as the enclosure itself in maintaining IP rating

- Ensure that the isolator itself is correctly rated and installed