Recent updates in the PV array installation standards and best practices have led to questions about the types of earthing and bonding in photovoltaic systems. This article aims to clarify what is meant then terms like earthing and bonding are used, and to briefly explain why each of these methods is needed.

Earthing possibilities/Types of Earthing?

The following options for earthing or bonding of parts of a PV array exist:

- Functional earthing of conductive non-current carrying parts.

- Equipotential bonding to avoid uneven potentials across the installation.

- Earthing for lightening protection.

- Functional earthing of one current carrying pole (conductor) of the PV array.

When is Functional Earthing implemented?

Functional earthing whether as per part (a) or (d) is required when the DC voltage of the PV system is above the Decisive Voltage Classification (DVC) – A category i.e.? 60V, as per IEC 62548.

Why functional earthing is implemented?

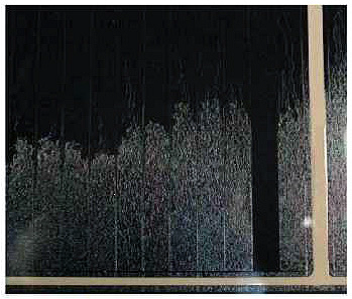

Some modules require functional earthing (as part (d) above) so that they operate correctly (performance) or so that they do not corrode internally. Thin film modules generally need to be negatively earthed, to prevent ‘bar-graph’ corrosion inside the module. Back-contact modules (i.e. Sunpower) need to be positively earthed to achieve their rated efficiency (See figure).

Functional earthing (as per part (a) above) and equipotential bonding are implemented to allow for better detection of leakage paths to Earth and to prevent electric shock.

What is Equipotential Bonding?

In the case of PV arrays, there are two forms of equipotential bonding:

- Main equipotential bonding: It is the connection of exposed conductive parts to the main earthing terminal.

- Supplementary equipotential bonding: It is the connection of exposed conductive parts to exposed conductive parts and/or extraneous conductive parts with a purpose of keeping the voltage in exposed conductive arts sufficiently low.

This conductor is then connected back to the earth in the MEN system, and must be a minimum of 6mm2 (as per IEC 62548).

Why do you need Equipotential Bonding?

When a PV array is connected to a PCE (especially transformerless), high frequency switching occurs within the inverter and can cause a small AC-like fluctuation in the array cables. The array cables are effectively capacitively coupled to the module frames, and over time this induces a voltage on the module frames and hence chances of electrical shock. To eliminate this voltage any array connected to a PCE needs to have equipotential bonding on all array frames and mounting rails.

What configurations are NOT recommended?

It is not recommended to connect a functionally earthed array (as per part (d)) to a transformerless (non-isolated) inverter. The configuration is not recommended due to the high probability that the inverter will introduce direct current into the AC electricity grid.

Learn about more such topics, best practices and international standards in GSES ‘Grid Connected PV Systems Design’ online course or read more in GSES ‘Grid Connected PV Systems Design and Installation’ Handbook. Visit www.gses.online/training or www.gses.online/publications for details.

Buy now using your credit or debit card on the GSES online shop (www.gses.in/shop).

Follow us on Facebook, Twitter and LinkedIn for more such updates.

Copyright GSES India Sustainable Energy Pvt. Ltd 2024